Dynamic Balancing rotors with precision

Dynamic balancing your rotating equipment.

Dynamic two plane balance of small hydro-electric turbine rotor by welding weights to the rotor. The dynamic balance was completed in overhung position.

Rotary screw dynamically balanced in two planes. Balancing of rotors was part of the complete rebuild of compressor.

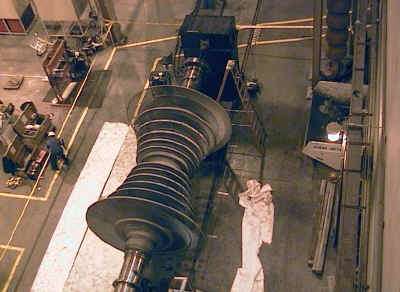

Dynamic balance of steam turbine rotor. Prime repaired rotor with new shaft and assembled all stages of rotor o new shaft.

Often there are issues with vibration, stress, or life expectancy of machinery that relate directly to the balancing of rotating equipment. Prime Machine has the capability to detect, monitor, and correct these issues, both in-house and on-site.

Balance is an especially sensitive issue in high-speed or precision equipment. It affects production rate and quality of product, as well as the lifespan of the equipment..

It has been documented by many large processing and production industries, that the money saved by longer equipment life and lowered maintenance costs, can drastically increase profits, product quality and customer satisfaction. Prime Machine also has a full condition monitoring program, that can be custom tailored to your facility. See our Predictive Maintenance Page.

Our custom built Balance Stand is designed so that it can be mounted to standard gauge railroad tracks. This gives our stand a very solid, ridged and safe foundation for the balancing of very large rotors, up to 300,000 lbs and almost twenty (20) feet in diameter.

Low Pressure Rotor being set into our Balance stand.

We direct couple our Hydraulic drive unit to the rotor which also controls any axial thrusting.

The rollers on the balance stand have a large surface/contact area, this prevent any marring or marking of the bearing journal areas.

Our Hydraulic Drive Unit is powered by a diesel engine which may be placed outside to eliminate smoke, fumes and noise from the work environment.

The Rotor is then spun up to between 150 and 200 rpm. Three runs are required to perform a balance calibration and then the final correction is made and verified.

Operator watching the tachometer and adjusting speed.

View of Rotor from the Turbine Deck.

This Rotor was balanced to:

.060mils @ 103° left and .026mils @ 315°

The residual imbalance was 35 oz/in in the left plane and 18 oz/in in the right plane.

The required correction weight would have been 1.447oz in the left plane

and .745oz in the right plane, on a 91,000lb rotor.

The entire Balance Unit will fit on our semi-trailer and is easily transportable anywhere within the United States and Canada.