In the fast-paced world of technology and manufacturing, staying ahead while maintaining older equipment can be a challenge. Obsolete components and parts with long lead times can significantly hinder progress and productivity. At Prime Machine Inc, we specialize in reverse engineering for obsolete components and long delivery items, offering a seamless solution from laser scanning to manufacturing.

Our Process:

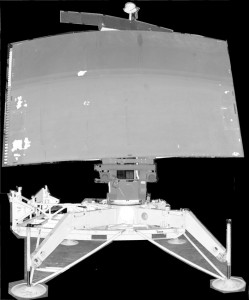

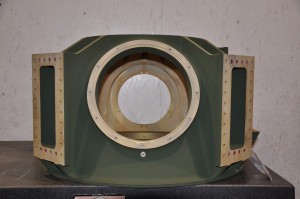

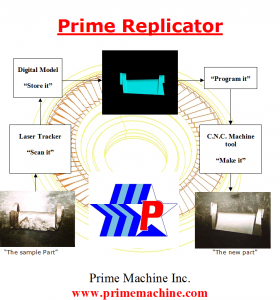

- Laser Scanning & Digitization: Our journey begins with precise laser scanning of your obsolete component. This non-invasive method captures the intricate tails of your part, ensuring every curve and angle is accurately documented. This digital twin serves as the foundation for our reverse engineering process.

- Material Analysis: Understanding the material composition is crucial. Our team conducts thorough material analysis to determine the exact specifications or the closest contemporary equivalent, ensuring the functionality and longevity of the component match the original.

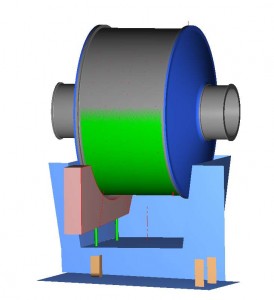

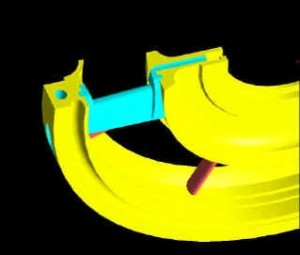

- Modeling with PolyWorks Software: Utilizing the industry-leading PolyWorks software, our skilled engineers transform scanned data into detailed 3D models. This step is pivotal, as it allows for the modification, analysis, and enhancement of the component design to meet current standards without losing its original functionality.

- Program Creation for Manufacturing: With a refined 3D model, we develop precise manufacturing programs. These programs guide our state-of-the-art CNC machines to produce components that are true to their original design or better, ensuring a perfect fit and function.

- Manufacturing of Mechanical Parts: The final step in our process is the manufacturing of your mechanical parts. Whether it’s a one-off piece or a small batch production, our advanced manufacturing facilities are equipped to handle your needs, delivering high-quality components that breathe new life into your legacy equipment.

Why Choose Us?

- Expertise in Diverse Industries: With years of experience across various sectors, we understand the unique challenges and requirements of each industry, offering tailored solutions that meet your specific needs.

- Cutting-Edge Technology: Leveraging the latest in laser scanning and 3D modeling technology ensures high accuracy and quality in every component we reproduce.

- Reduced Downtime: Our efficient process minimizes the time your equipment is out of commission, helping you maintain productivity and meet your operational goals.

- Cost-Effective Solutions: Avoid the high costs associated with equipment upgrades or long lead times for parts. Our reverse engineering services offer a cost-effective alternative to keep your machinery running smoothly.

Get Started Today

If you’re facing challenges with obsolete components or parts with long lead times, contact us today. Our team is ready to assist you in finding the best solution to extend the life of your equipment and keep your operations moving forward.

Contact US

Discover how Prime Machine Inc can help you overcome the obstacles of obsolete components and long lead times with our comprehensive reverse engineering services. Explore our website or reach out directly to learn more about our process and how we can tailor our services to meet your needs.