Machine Tool Repair and Calibration

Prime Machine is your resource for Machine Tools repair. We have skilled craftsmen with modern tools to complete rebuilds: Vibration analysis to determine where the problem exists. Ball bar measurements for checking machine encoders and drives for accuracy, and laser trackers to measure overall machine geometry. We have technicians trained and capable of scraping ways.

Setting horizontal table on newly ground ways of bed. Adjusting of Gibbs on older style machine. |

Laser Tracker measuring machine geometry to verify square of axis and setting encoder calibration.

ISO Certified, NIST Traceable Inspection and Calibration Services.

The portable CMM or Laser Tracker is an excellent choice for calibration and analysis of machine tools. It is not size limited and can check wear, axis alignment, scale calibration, geometry, rotary axis calibration, level, and many more features with extreme accuracy.

Machine tool design, repairs, upgrades and calibration.

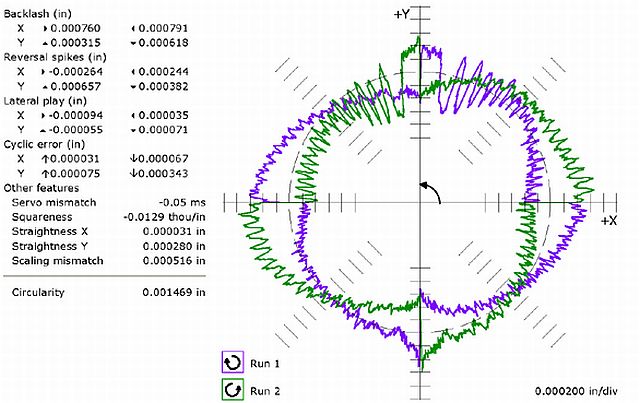

The Renishaw Ballbar System is based around a ball-ended bar-length transducer which is held magnetically and kinematically between machine spindle and a specially designed magnetic base clamped to the machine bed. The CNC machine is programmed to describe a circle and the Ballbar transducer detects deviations which indicate inaccuracies in the machine tool path. From this data, the PC-based Renishaw Software can derive volumetric accuracy, Squareness values, repeatability, backlash, contouring ability, linearity XYZ and servo performance.